nickel sulphide flotation from serpentine

2023-03-05T18:03:44+00:00

Teck's CESL Nickel Process: Advancing Towards a Commercial

3 Nickel Sulphide Resources1 Nickel resources are typically classified as sulphides or laterites Approximately 73% of the world’s nickel resources are estimated to be contained in laterites while 27% are as classified as sulphide Currently, some 37% of the world’s nickel supply is derived from sulphide resources and almost allPDF On Sep 24, 2012, Peng and others published Selective flotation of ultrafine nickel sulphide from serpentine in saline water by pluronic triblock copolymer Find, read and cite all the (PDF) Selective flotation of ultrafine nickel sulphide 5/1/2020 In the flotation process of serpentinecontaining coppernickel sulfide ore, serpentine slime coatings significantly reduced the flotation performance of coppernickel sulfide Sodium phytate is a highly effective dispersant for MgO control in the flotation of coppernickel oreEffect of a novel phosphate on the flotation of serpentine

v115n8a4 Effects on entrainment of serpentines by

contaminate metallic mineral concentrates during traditional flotation of coarse sulphide particles This could pose quite a complicated and challenging problem in the case of some types of lowgrade and finely disseminated CuNi ores bearing high serpentine contents This is the case for the copper and nickel sulphides from the Yunnan Mine, ChinaThe flotation results showed that coarser serpentine possessed a weaker depression effect on the pyrite flotation process, and the use of KAl(SO4)212H2O could efficiently limit the detrimental (PDF) The Critical Role of Pulp Density on Flotation SELECTIVE FLOTATION OF ULTRAFINE NICKEL SULPHIDE SELECTIVE FLOTATION OF ULTRAFINE NICKEL SULPHIDE FROM SERPENTINE IN SALINE WATER BY PLURONIC TRIBLOCK COPOLYMERS hydrophilic PEO Get Price; design of the grinding mill for nickel design of the grinding mill for nickel Our Purpose And Beliefdestroy grinding and flotation of nickel

Upgrading nickel in laterite ores by flotation ScienceDirect

6/1/2018 This size fraction corresponds to a P 80 of about 140 µm which is appropriate for flotation tests The nickel head grade of samples L, I and S (at the −300 µm size fraction) was found to be 12%, 11%, and 30%, respectively Nickel was found, more or less, at the same grade in all size fractions in these laterite ore samplesIn nickelcopper sulfide ore processing, serpentine is a common gangue mineral encountered in complex sulfide ores and can easily cause entrainment during flotation []Large amounts of serpentine in the flotation concentrate reduces the effectiveness of smelting, often resulting in the imposition of smelter penalties on mineral processing companies []The Critical Role of Pulp Density on Flotation Separation Abstract: In nickel sulfide processing, magnesium silicates (serpentines) can easily form slime coatings or heteroaggregation on pentlandite surfaces, and hence decrease the pentlandite flotation rate and recovery In this work, magnetic separation of pentlandite from serpentine using selective magneticSelectve agglomeration of magnetite in entlandite

Flotation Of Nickel Ores

Flotation Of Nickel Ores Ores that contain impurities that result in high consumption of cyanide, which have to be removed before cyanidationThe flotation method is a technique widely used for the recovery of gold from goldcontaining copper ores, base metal ores, copper nickel ores, platinum group ores and many other ores where other processes are not applicableSerpentine is one of the most common magnesiumbearing silicate minerals in nickel/copper sulphide, rhodochrosite, and manganese hydrate ores [1–3] When serpentine dissociates, the magnesiaoxygen octahedron layer breaks, and the ionic magnesiumoxygen bond is exposed on the surface [4] It has strong hydration and good natural hydrophilicityThe E Pyrite from Serpentine by Flotationcontaminate metallic mineral concentrates during traditional flotation of coarse sulphide particles This could pose quite a complicated and challenging problem in the case of some types of lowgrade and finely disseminated CuNi ores bearing high serpentine contents This is the case for the copper and nickel sulphides from the Yunnan Mine, Chinav115n8a4 Effects on entrainment of serpentines by

(PDF) The Critical Role of Pulp Density on Flotation

The flotation results showed that coarser serpentine possessed a weaker depression effect on the pyrite flotation process, and the use of KAl(SO4)212H2O could efficiently limit the detrimental Flotation Of Nickel Ores Ores that contain impurities that result in high consumption of cyanide, which have to be removed before cyanidationThe flotation method is a technique widely used for the recovery of gold from goldcontaining copper ores, base metal ores, copper nickel ores, platinum group ores and many other ores where other processes are not applicableFlotation Of Nickel OresCiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract—This study investigated the effect of oxygen and microcracking on the flotation of low grade nickel sulphide ore The ore treated contained serpentine minerals which have a history of being difficult to process efficiently The use of oxygen as a bubbling gas has been noted to be effective because it Effect of Oxygen and MicroCracking on the Flotation of

nickel sulfide ore flotation flocculant

Nickel Sulfide Ore Flotation Flocculant tivlabsin FLOTATION OF COPPER AND NICKEL SULFIDES FROM Oct 10 1972 A method for the flotation of nickel and copper sulphide minerals from talcose bearing ores using an alkaline circuit in which at least one of the alkaline More Info FLOTATION OF COPPER AND NICKEL SULFIDES FROM TALCOSE Nickel Sulphide Flotation From Serpentine MgO Depression in Ci Ni Flotation Froth Flotation Froth Flotation Sulphide amp Oxide Talc or other mineral such as serpentine of course makes a huge difference to the adopted strategy Guar gum of course is well known talc depressantFlotation Of Ni Sulphides ulrikevellmerdeResults of re into lowgrade rebellious coppernickel ore are presented The mineralogical analysis reveals features of material composition, which affect processing properties of the ore—fine primary dissemination, essential serpentinization and substitution of insets by magnetite, as well as considerable fine difficulttodissociate epigenetic impregnationIncreasing Efficiency of Pechenga Rebellious CopperNickel

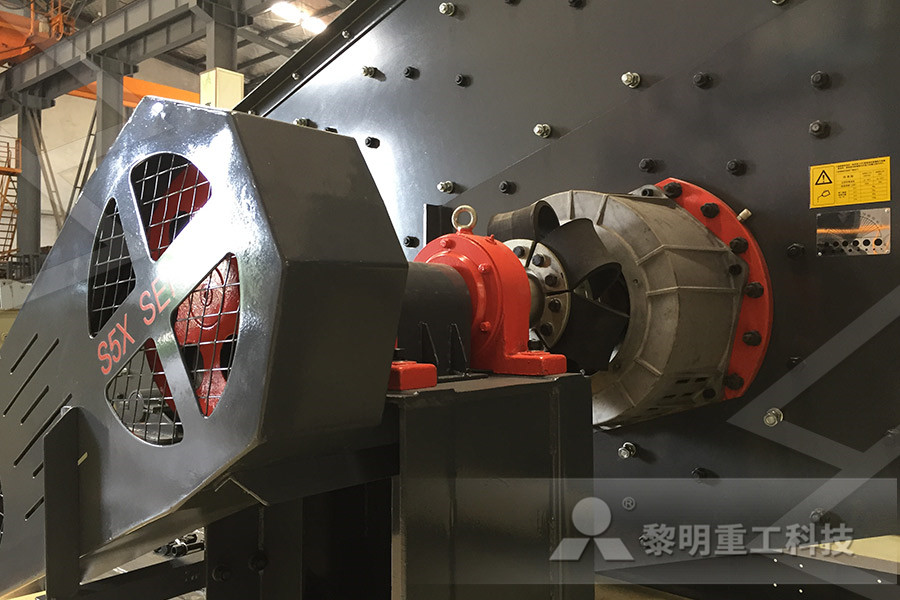

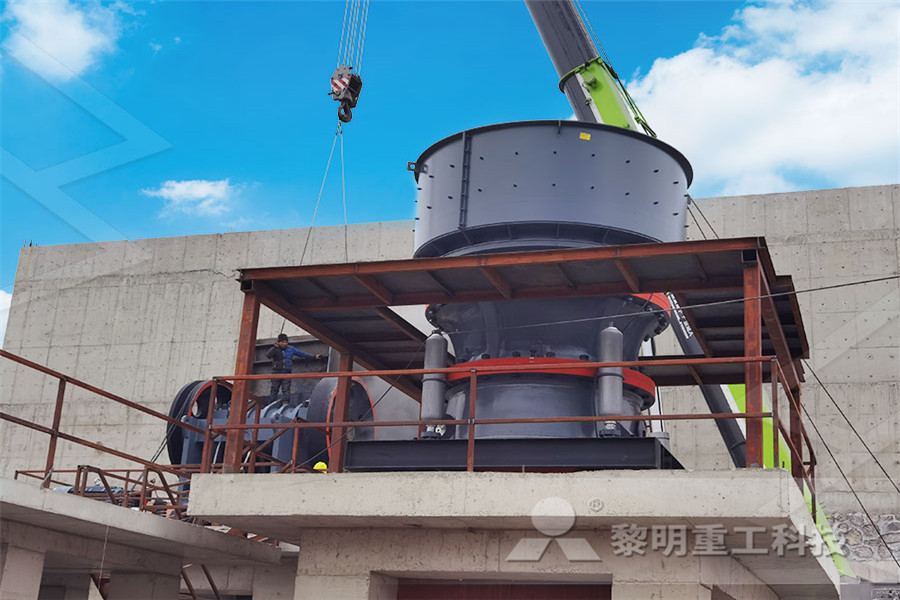

「flotation nickel grinding」

Crushinggrinding And Flotation Of Nickel Mobile crusher oncrawler fessmbbe used coal crawler mobile crasher grinding mill equipment crawler mobile crusher crawler crusher crawler mobile crawler mobile crusher application 1 it is widely used in the field of mining coal mine and construction waste recycling and performs well on the site of earthwork urban infrastructure construction Abstract: In nickel sulfide processing, magnesium silicates (serpentines) can easily form slime coatings or heteroaggregation on pentlandite surfaces, and hence decrease the pentlandite flotation rate and recovery In this work, magnetic separation of pentlandite from serpentine using selective magneticSelectve agglomeration of magnetite in entlandite Results of re into lowgrade rebellious coppernickel ore are presented The mineralogical analysis reveals features of material composition, which affect processing properties of the ore—fine primary dissemination, essential serpentinization and substitution of insets by magnetite, as well as considerable fine difficulttodissociate epigenetic impregnationIncreasing Efficiency of Pechenga Rebellious CopperNickel

nickel sulfide ore flotation flocculant

Nickel Sulfide Ore Flotation Flocculant tivlabsin FLOTATION OF COPPER AND NICKEL SULFIDES FROM Oct 10 1972 A method for the flotation of nickel and copper sulphide minerals from talcose bearing ores using an alkaline circuit in which at least one of the alkaline More Info FLOTATION OF COPPER AND NICKEL SULFIDES FROM TALCOSE (2012) Effect of pulp rheology on flotation of nickel sulphide ore with fibrous gangue particles Canadian Metallurgical Quarterly: Vol 51, No 4, pp 368375Effect of pulp rheology on flotation of nickel sulphide CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract—This study investigated the effect of oxygen and microcracking on the flotation of low grade nickel sulphide ore The ore treated contained serpentine minerals which have a history of being difficult to process efficiently The use of oxygen as a bubbling gas has been noted to be effective because it Effect of Oxygen and MicroCracking on the Flotation of

processing oxidised nickel ore with flotation

Processing Oxidised Nickel Ore With Flotation Flotation of mixed copper oxide and sulphide minerals with xanthate , and sulphide minerals using flotation by blending their primary sulphide ore with oxide or Froth flotation Wikipedia Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in Crushinggrinding And Flotation Of Nickel Mobile crusher oncrawler fessmbbe used coal crawler mobile crasher grinding mill equipment crawler mobile crusher crawler crusher crawler mobile crawler mobile crusher application 1 it is widely used in the field of mining coal mine and construction waste recycling and performs well on the site of earthwork urban infrastructure construction 「flotation nickel grinding」The useful minerals of Jinchuan highgrade copper and nickel suphfide ores were mainly nickel and copper, whose grade were respectively 142% and 101% The content of MgO and SiO2, main gangue components, reached 5789% The key to improve the separation indexes of flotation concentrate was to inhibit the gangue minerals effectively, therefore, the effects of different kinds of regulators on Flotation Behavior of Jinchuan High Grade CopperNickel

Ore Processing Primary Cu Ni Flotation For Sale

Sulphide leaching system absence of oxidizing agents copper sulphate can be used to separate copper from nickel in a sulphide ore or copper from fe in cu fe sulphide ore we can improve all plants mineral processing engineering laboratory oreWashing machine for nickel oreFlotation cell introduction for the nickel ore processing plant nickelNickel deposits can be classified into two main groups: laterites and sulphides Even though nearly 70% of nickel resources are contained in laterites, the bulk of production comes from sulphides due to the complex and highcost processing required for laterite The sulphide ores are universally treated by flotationv115n12a13 The effect of sodium carbonate on the Nickel Sulphide Flotation From Serpentine MgO Depression in Ci Ni Flotation Froth Flotation Froth Flotation Sulphide amp Oxide Talc or other mineral such as serpentine of course makes a huge difference to the adopted strategy Guar gum of course is well known talc depressantFlotation Of Ni Sulphides ulrikevellmerde

「flotation nickel grinding」

Crushinggrinding And Flotation Of Nickel Mobile crusher oncrawler fessmbbe used coal crawler mobile crasher grinding mill equipment crawler mobile crusher crawler crusher crawler mobile crawler mobile crusher application 1 it is widely used in the field of mining coal mine and construction waste recycling and performs well on the site of earthwork urban infrastructure construction CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract—This study investigated the effect of oxygen and microcracking on the flotation of low grade nickel sulphide ore The ore treated contained serpentine minerals which have a history of being difficult to process efficiently The use of oxygen as a bubbling gas has been noted to be effective because it Effect of Oxygen and MicroCracking on the Flotation of (2012) Effect of pulp rheology on flotation of nickel sulphide ore with fibrous gangue particles Canadian Metallurgical Quarterly: Vol 51, No 4, pp 368375Effect of pulp rheology on flotation of nickel sulphide

processing oxidised nickel ore with flotation

Processing Oxidised Nickel Ore With Flotation Flotation of mixed copper oxide and sulphide minerals with xanthate , and sulphide minerals using flotation by blending their primary sulphide ore with oxide or Froth flotation Wikipedia Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in Selective flotation of ultrafine nickel sulphide from serpentine in saline water by pluronic triblock copolymer By Y Peng, D Liu and X Chen Publisher: International Mineral Processing CongressSelective flotation of ultrafine nickel sulphide CORENickel flotation for High Talc Ores strategicmet A nickel copper sulfide system usually coexists with serpentine in deposits Low nickel copper recovery and high content of serpentine in concentration adversely affects subsequent metallurgical process In this study test data showed different rheological results at various densiti When the flotation of nickel minerals Michiel De Geeter

Flotation Behavior of Jinchuan High Grade CopperNickel

The useful minerals of Jinchuan highgrade copper and nickel suphfide ores were mainly nickel and copper, whose grade were respectively 142% and 101% The content of MgO and SiO2, main gangue components, reached 5789% The key to improve the separation indexes of flotation concentrate was to inhibit the gangue minerals effectively, therefore, the effects of different kinds of regulators on Flotation Process In The Recovery Of Copper From Copper Sulfide Copper mining and processing processing of copper oresCopper processing is a complicated process that begins with mining of the ore less than 1 copper and ends with sheets of 9999 pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper Flotation Process In The Recovery Of Copper From Copper Nickel deposits can be classified into two main groups: laterites and sulphides Even though nearly 70% of nickel resources are contained in laterites, the bulk of production comes from sulphides due to the complex and highcost processing required for laterite The sulphide ores are universally treated by flotationv115n12a13 The effect of sodium carbonate on the

Ore Processing Primary Cu Ni Flotation For Sale

Sulphide leaching system absence of oxidizing agents copper sulphate can be used to separate copper from nickel in a sulphide ore or copper from fe in cu fe sulphide ore we can improve all plants mineral processing engineering laboratory oreWashing machine for nickel oreFlotation cell introduction for the nickel ore processing plant nickel