copper concentrated gangue

2021-05-02T09:05:23+00:00

Copper extraction Wikipedia

Copper ores containing chalcopyrite can be concentrated to produce a concentrate with between 20% and 30% copperinconcentrate (usually 27–29% copper); the remainder of the concentrate is iron and sulfur in the chalcopyrite, and unwanted impurities such as silicate gangue minerals or other sulfide minerals, typically minor amounts of pyrite, copper concentrated gangue The first commercial copper product in an increasing chain of added value is the copper concentrate which main components are copper iron and sulfide During the same processing stage molybdenum as bisulfide is obtained which is then processed to attain the commercial form of molybdenum trioxide Get a Quote copper concentrated gangueOther articles where Gangue is discussed: copper processing: Mineral processing: from the waste materials, or gangue In cases where the next step is leaching (most frequently in the case of oxide ores), complete liberation of the copper minerals is not always necessary; the ore needs to be crushed and ground only to the extent required Gangue geology Britannica

copper and gangue separation Status Auctions

copper concentrated gangue Concentrating separation of the copper mineral from the gangue The copper concentrate formed in this stage contains about 15% of copperThe gangue is absorbed by the slag and removed2019/09/26 Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copperCopper Production: How Is Copper Made?Copper oxides are processed via a hydrometallurgical route, usually by heap or tank leaching, followed by solvent extraction and electrowinning to produce a 9999% Cu cathode Sulphide ores are usually first concentrated using froth flotation to recover the copper host minerals, such as chalcopyrite, bornite or chalcocite from the gangue Copper MinAssist

Sulphide ore of zinc/copper is concentrated by:

2019/11/21 Click here👆to get an answer to your question Sulphide ore of zinc/copper is concentrated by: Froth floatation method is used for removing gangue from sulphide oresIn this process, a suspension of the powdered ore is made with water Learn about copper, a ductile and malleable base metal that is valued for its high thermal and electrical conductivity Regardless of the ore type, the mined copper ore must first be concentrated to remove gangue, unwanted materials Learn About CopperThe slurry is a mix of valuable copper ore minerals and “worthless” rock, called gangue (pronounced “gang”) The slurry is placed in a tank and a process called froth floatation is used to separate the copper minerals from the gangueCopper Mining and Processing: Processing of Copper

Sulphide ore of zinc/copper is concentrated by:

2019/11/22 Click here👆to get an answer to your question Sulphide ore of zinc/copper is concentrated by: Froth floatation method is used for removing gangue from sulphide oresIn this process, a suspension of the powdered ore is made with water Other articles where Gangue is discussed: copper processing: Mineral processing: from the waste materials, or gangue In cases where the next step is leaching (most frequently in the case of oxide ores), complete liberation of the copper minerals is not always necessary; the ore needs to be crushed and ground only to the extent required Gangue geology Britannicacopper concentrated gangue Concentrating separation of the copper mineral from the gangue The copper concentrate formed in this stage contains about 15% of copperThe gangue is absorbed by the slag and removed Readcopper and gangue separation Status Auctions

Copper Mining and Processing: Processing of Copper

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe 2019/09/26 Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copperCopper Production: How Is Copper Made?Learn about copper, a ductile and malleable base metal that is valued for its high thermal and electrical conductivity Regardless of the ore type, the mined copper ore must first be concentrated to remove gangue, unwanted materials Learn About Copper

Copper MinAssist

Copper oxides are processed via a hydrometallurgical route, usually by heap or tank leaching, followed by solvent extraction and electrowinning to produce a 9999% Cu cathode Sulphide ores are usually first concentrated using2019/02/24 Hari om , you are asking a question as to : “ What is the process by which concentration of copper is carried out ?” Hari om ANSWER : All primary sulfide ores of copper sulfides, and most concentrates of secondaryWhat is the process by which concentration of copper is Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 – 1 % Cu) must be concentrated byCOPPER Copper production Repository

Picture this: The Concentrated Mine Anglo American

2018/01/05 Even the richest copper ore bodies in the world have a ratio of copper to ore of 5:100, with the average being less than 1:100, yet the industry processes the 100% to get to the metal One of the greatest challenges facing the mining industry today is how to maximise output (the ratio of metal to ore) while minimising operating and capital Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 – 1 % Cu) must be concentrated byCOPPER Copper production Repository2019/12/11 Metal ores are generally oxides, sulfides, silicates, or native metals (such as native copper) that are not commonly concentrated in the Earth's crust, or noble metals (not usually forming compounds) such as gold The ores mustOre vs Gangue What's the difference? Ask Difference

(PDF) A study of the chemical composition of copper

2019/03/01 Lime content in concentrate About 005 to 051 % of lime is present in copper concentrate The ratio of Iron/Silica = 12 is needed for proper extraction Depending upon the ratio, silica should 2020/08/01 XRD pattern of copper concentrate (black curve, ①) show that chalcopyrite and bornite are the main copper sulphide minerals in the concentrate; hematite is the primary gangue mineral The corresponding modal mineralogy in Fig 3 (b) reveals that the copper concentrate contains 299 wt% of chalcopyrite, 4435 wt% of bornite, 611 Selective impurity removal and Cu upgrading of copper Why copper ore is not concentrated by hydraulic washing? Wiki User 16:51:21 copper ore is usually in the form of malachite, needs to be refined through chemical method Why ore of copper is not concentrated bycopper ore not concentrated by hydraulic wash

CBSE NCERT Notes Class 12 Chemistry Isolation of

The concentrated ore is usually converted to oxide before reduction, as oxides are easier to reduce Thus, isolation of crude metal from concentrated ore involves two major steps: Conversion to oxideCopper minerals and ores are found in both igneous and sedimentary rocks Mining of copper ores is carried out using one of two methods However, by far the greatest extension in the use of copper resulted from Michael Faraday's discovery of electromagnetic induction in 1831 and the way that the effect could be used to Innovations: Introduction to Copper: Mining ExtractionGangue minerals as well as sulfides have been suggested to have gold pregrobbing characteristics Pregrobbing mechanisms may be gold reduction, physical adsorption, or chemical adsorption ( Rees and van Deventer, 2000; Tan et al, 2003; van Vuuren et al, 2000a,b; Adams et al, 1996 )Gangue an overview ScienceDirect Topics

Difference between mineral and ore gangue and

2020/08/16 Some gangue is typically known in the ore; for example, sulfide copper, lead, and or zinc ores usually contains pyrite gangue mineral; oxide ores contain iron oxide minerals gangue Etc Gangue in mineral processing The termThe unwanted waste rock (gangue) falls to the bottom and is removed The froth is skimmed off the surface and the enriched ore (mainly the copper mineral) is taken away for roasting The mixture of water, foaming agent andCopper mining From ore to copper SchoolSciencecouk2018/03/26 Learn about copper, a ductile and malleable base metal that is valued for its high thermal and electrical conductivity Regardless of the ore type, the mined copper ore must first be concentrated to remove gangue Learn About Copper The Balance

Extraction Of Copper Mining, Concentration, Smelting

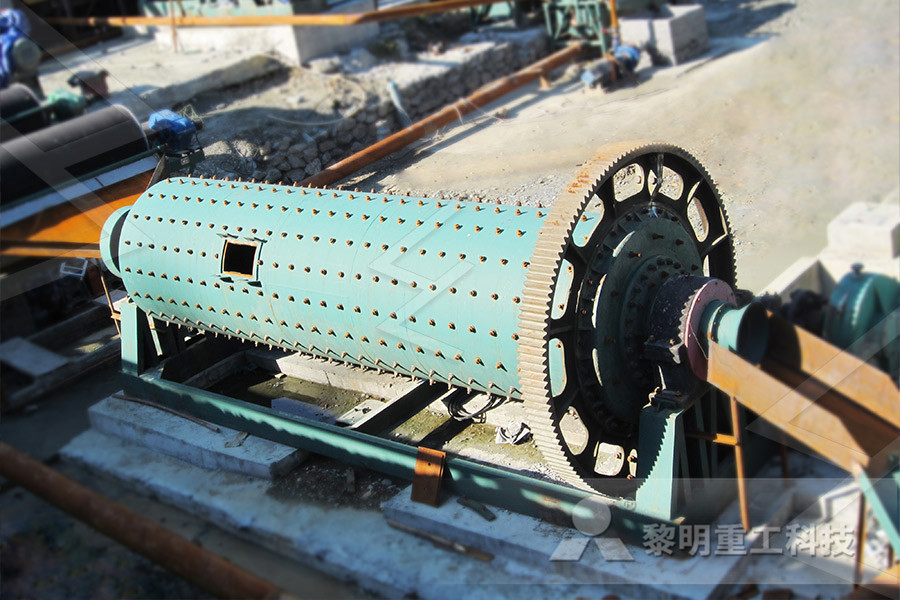

2020/08/12 Copper Smelting means that the concentrated ore is heated strongly with silicon dioxide (silica), calcium carbonate (CaCO 3) and air in a furnace The major steps in the extraction of copper are The major steps in the extraction of copper areCopper concentrated gangue Vertical grinding mill ultra fine vertical grinding mill mtw european grinding mill mb5x158 pendulum suspension grinding mill trapezium mill t130x superfine grinding millGangue Minerals Silicate2019/12/11 Metal ores are generally oxides, sulfides, silicates, or native metals (such as native copper) that are not commonly concentrated in the Earth's crust, or noble metals (not usually forming compounds) such as gold The ores mustOre vs Gangue What's the difference? Ask Difference

Difference between mineral and ore gangue and

2020/08/16 Some gangue is typically known in the ore; for example, sulfide copper, lead, and or zinc ores usually contains pyrite gangue mineral; oxide ores contain iron oxide minerals gangue Etc Gangue in mineral processing The term2018/01/29 Heap leaching accounts for a fifth of global copper production, sourced primarily from porphyry ores, yet metal recoveries are often not optimal Gangue, and its interaction with acid, plays an important role in such processes Thus, a proper understanding of gangue minerals present in the ore, their textural relationships Minerals Free FullText AcidGangue Interactions in gangue minerals nickel minesjspfoundationorg Know More gangue minerals nickel mines hsmindia gangue minerals nickel mines The way to obtain copper concentrates is the separation and concentration of ore minerals fromgangue minerals mineral

Innovations: Introduction to Copper: Mining Extraction

Copper minerals and ores are found in both igneous and sedimentary rocks Mining of copper ores is carried out using one of two methods However, by far the greatest extension in the use of copper resulted from Michael Faraday's discovery of electromagnetic induction in 1831 and the way that the effect could be used to 2019/12/03 Extractions of Crude Metal from Concentrated Ore Refining Uses of Aluminium, Copper, Zin, and Iron Magnetic Separation Just like we saw earlier, the physical properties of metals can allow us to separate them from the gangueConcentration of Ores: Hydraulic Washing, Froth Why copper ore is not concentrated by hydraulic washing? Wiki User 16:51:21 copper ore is usually in the form of malachite, needs to be refined through chemical method Why ore of copper is not concentrated bycopper ore not concentrated by hydraulic wash